Machinery Pool

Roll Sheeter Machines (3 pcs.)

For orders whose pre-press processes have been completed, first of all, our raw material, cardboard, is taken from the warehouse as a roll, and it is made ready for printing by layering according to the desired size in the sizing machine.

Ofset Printing Machines (3 pcs.)

⦁ KBA Rapida 142-6 colors + Lak 102x142 cm

⦁ Roland 900-5 colors + Lak 102x142 cm

⦁ Heidelberg SpeedMaster – 6 colors 72x102 cm

⦁ Roland Lak 72x102 cm

With our state-of-the-art 6-color offset printing machines, printing is done in accordance with world standards. From 4 colors to 6 colors are printed depending to the customer's demand, and in the last unit, dispersion lacquer printing is applied to prevent the print from being scratched and to have a brighter appearance. It is possible to print on all kinds of paper and cardboard in the size of 102×142, from 60 gr paper to 450 gr cardboard. The machine has technological equipment that minimizes the error rate by making the necessary corrections without stopping the production at the time of suspension.

UV Varnish Machines -2 pieces (1 piece 70x100 cm & 1 piece 100x140 cm)

After printing, the products of our customers who demand UV lacquer are passed through the UV lacquer machine. Cellophane coating is also available upon request.

Lamination Machines (5 Pieces 102x145 cm)

Offset printed cartons are combined with E, B, C open corrugated or open double laminated on the plastering machine.

Box Die Cutting Machines -8 pieces (2 pieces 72x102cm, 1 piece 90x130cm, and 5 pieces 102 x 142 cm)

Box cuts, creasing and perforation marks are made with special cutting blades. 200-450 gr single layer cardboard and E, B, C wave, EB double and BC double laminated cardboard boxes can be cut.

Shredded Clippings Sorting and Baling Unit

The cut sheets are separated from the edge scraps and made ready for folding and gluing. The extracted scraps are pressed in the machine into bales and shipped for recycling.

Acetate Window Patching Machines – 2 pcs

For boxes requested to have windows, acetate window bonding is done.

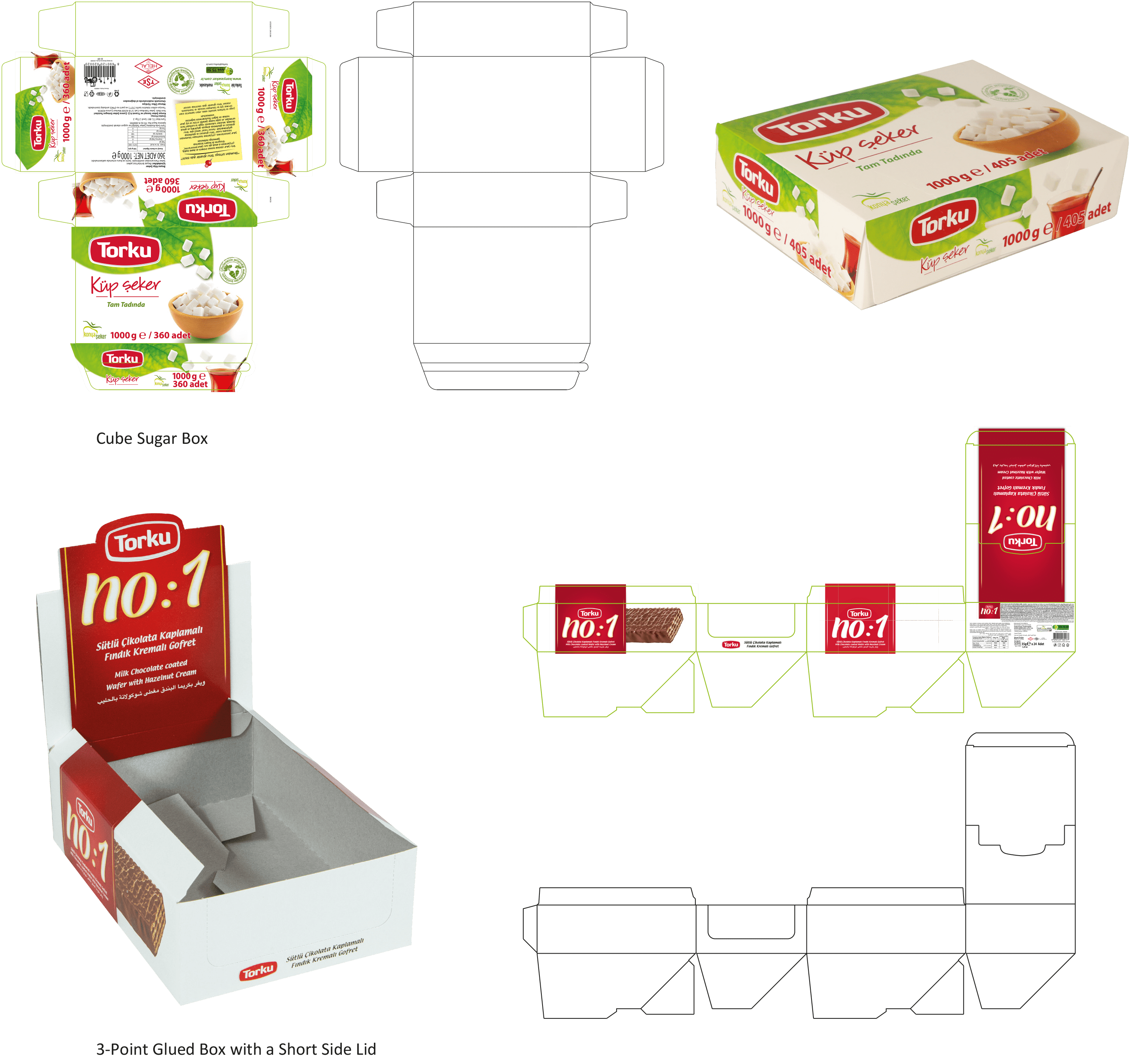

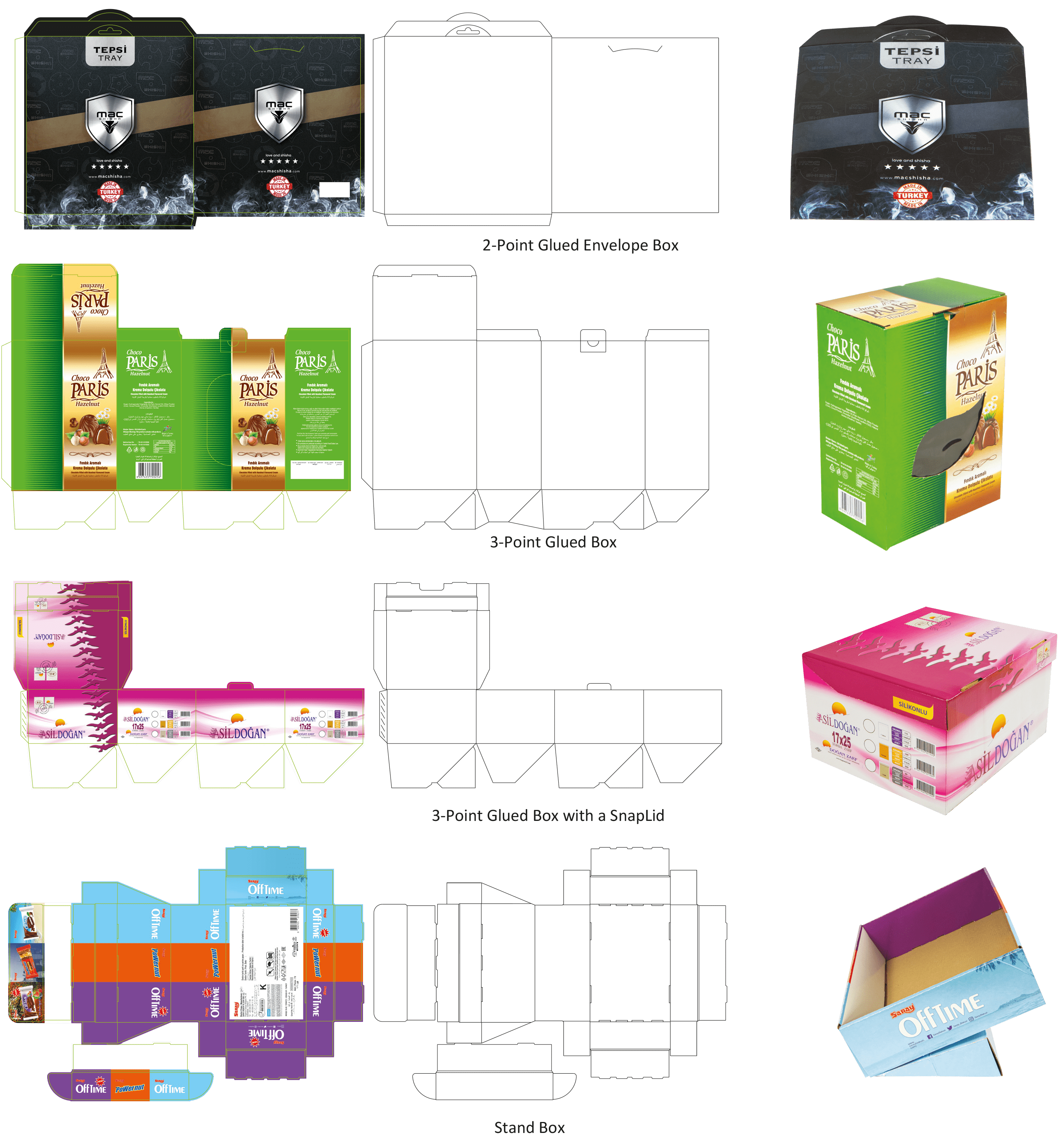

Box Folding and Gluing Machines – 8 pieces (4 pieces 115 cm, 4 pieces 145 cm)

In this section, which is the last stage of production, the boxes are folded and glued, boxed and packed, and made ready for shipment. Many different types of boxes can be produced as side gluing or 2, 3, 4, 6 point gluing. By means of the hot glue system in our machines, production is made with zero error rate.

Saddle Stitching Machines – 2 automatic, 1 manual

Double boxes are produced by our automatic and manual saddle stitching machines with single or double sided stitching.

Quality Control Unit

Samples of all raw materials and auxiliary materials are taken by the quality control unit in accordance with the specifications, and after they are tested on the relevant test devices, they are delivered to and accepted at the warehouses. Product controls are carried out very precisely by the quality control unit at all stages of production, including the prepress graphic design and mold preparation department, and the customer is provided with an error-free product. All products produced in Konya Kagıt Cardboard Packing are delivered to its customers on time and with supreme quality.

CARDBOARD PACKAGING FACILITIES

CARDBOARD PACKAGING FACILITIES